As a sheet piling specialist, Sterk has already made hundreds of construction pits with sheet piling. Vibration-free, low-vibration, anchoring, stamping… we can do it all!

- Design & Engineeringg

- Sheet piling, welding and construction work

- Vibration-free or Low-vibration

The importance of maintenance and improvement of the Dutch dykes will only increase in the future. At Sterk we have a lot of experience with both small and large dyke reinforcement projects.

- Vibration-free or Low-vibration

- From land or water

- Eye for surroundings

Sterk places sheet piling for the land abutments. But we can also take care of the foundation and any required fender structures.

- Foundation, abutments and quay improvements

- Sheet piling, tubular piles, concrete piles

- Fender structures

Sterk realises several underpasses every year, often in a very short time. Meticulous planning and good communication are crucial. That means you want to work with an experienced partner.

- Design & Engineering

- Sheet piling, welding and construction work

- Contributing ideas, communicating and planning

No parking garage without sheet piling. Garages with two, three, four or even five layers: Sterk has already made numerous such constructions, often with a bracing frame or anchoring construction.

- ODesign, engineering and realisation

- Vibration-free or low vibration

- Bracing frame and/or anchoring

Sterk builds new loading or unloading quays and renovates obsolete quays. We perform the construction from land or water. Vibration-free or low-vibration.

- Vibration-free or low vibrations

- Minimise nuisance

- From land and/or water

Sterk

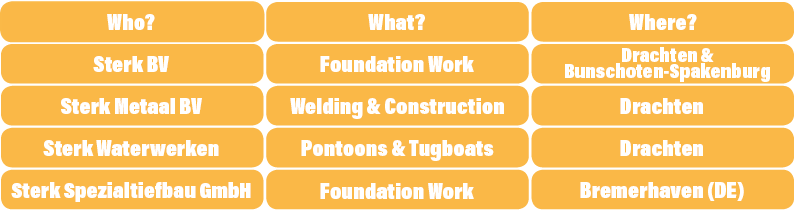

Sterk BV developed from a small family business into THE foundation specialist in the Netherlands and far beyond. With almost a century and a half of experience in the field of piling and innovative foundation techniques, we are a flexible partner for every project.

Sterk makes construction pits, dyke reinforcements, quay renovations, sediment basins, underpasses and more. And no two projects are the same. That’s why we often come up with project-oriented solutions. Do not hesitate to contact us for questions about your project.

Highlighted project: Flood Barrier IJmuiden

The new sea lock being constructed in IJmuiden is an extraordinary project. Rijkswaterstaat, the national agency responsible for public works and water management in the Netherlands, awarded the contract for its construction to the OpenIJ consortium. With a length of 500 metres and a width of 70 metres, it will be the largest sea lock in the world.

In early 2017, Sterk installed sheet piling for a temporary landing wharf, but the real work only started this autumn! For a temporary flood barrier we had to install piles of no less than 27 metres in length. To make it even more challenging, these piles had to be put in place with our Silent Piler using the ‘press-in’ technique – and all this at 7 metres above sea level. This meant that, depending on the tide, the press-in machine would be suspended at between 6 and 8 metres above the water…

Highlighted project: Combined Wall Zeebrugge

Sterk provided a large combined wall construction to serve as a quay wall in the port of Zeebrugge. More than 200 tubular piles measuring approx. 30 metres and interlocking sections of approx. 20 metres had to be driven into the ground. This resulted a combi wall of more than 600 metres.

Work was carried out as part of the extension of the Hanze Terminal, one of Europe’s most important hubs for the import and export of vehicles.

Sterk is not new to building combi walls, but works on this scale are an exception. Not only did the job involve the construction of 220 tubular piles measuring up to 30 m long and 1.3 m in diameter, but also the 20 m long interlocking sections. The combi wall had to be anchored, and so we installed anchor plates attached to the combi wall by means of anchor rods as well. In this way, the entire construction became even more robust.

Highlighted project: Flood Barrier IJmuiden

The new sea lock being constructed in IJmuiden is an extraordinary project. Rijkswaterstaat, the national agency responsible for public works and water management in the Netherlands, awarded the contract for its construction to the OpenIJ consortium. With a length of 500 metres and a width of 70 metres, it will be the largest sea lock in the world.

In early 2017, Sterk installed sheet piling for a temporary landing wharf, but the real work only started this autumn! For a temporary flood barrier we had to install piles of no less than 27 metres in length. To make it even more challenging, these piles had to be put in place with our Silent Piler using the ‘press-in’ technique – and all this at 7 metres above sea level. This meant that, depending on the tide, the press-in machine would be suspended at between 6 and 8 metres above the water…

Highlighted project: Combined Wall Zeebrugge

Sterk provided a large combined wall construction to serve as a quay wall in the port of Zeebrugge. More than 200 tubular piles measuring approx. 30 metres and interlocking sections of approx. 20 metres had to be driven into the ground. This resulted a combi wall of more than 600 metres.

Work was carried out as part of the extension of the Hanze Terminal, one of Europe’s most important hubs for the import and export of vehicles.

Sterk is not new to building combi walls, but works on this scale are an exception. Not only did the job involve the construction of 220 tubular piles measuring up to 30 m long and 1.3 m in diameter, but also the 20 m long interlocking sections. The combi wall had to be anchored, and so we installed anchor plates attached to the combi wall by means of anchor rods as well. In this way, the entire construction became even more robust.